Looking for automotive wire harnesses manufacturers? Look no further than your 5-star-rated company – Pinnacle Harnesses.

Automotive wire harnesses are the unsung heroes of modern vehicles, ensuring the seamless transmission of electrical power and data between various components and systems within a vehicle.

These carefully engineered assemblies play a crucial role in maintaining vehicle functionality, safety, and reliability.

Automotive Wire Harnesses

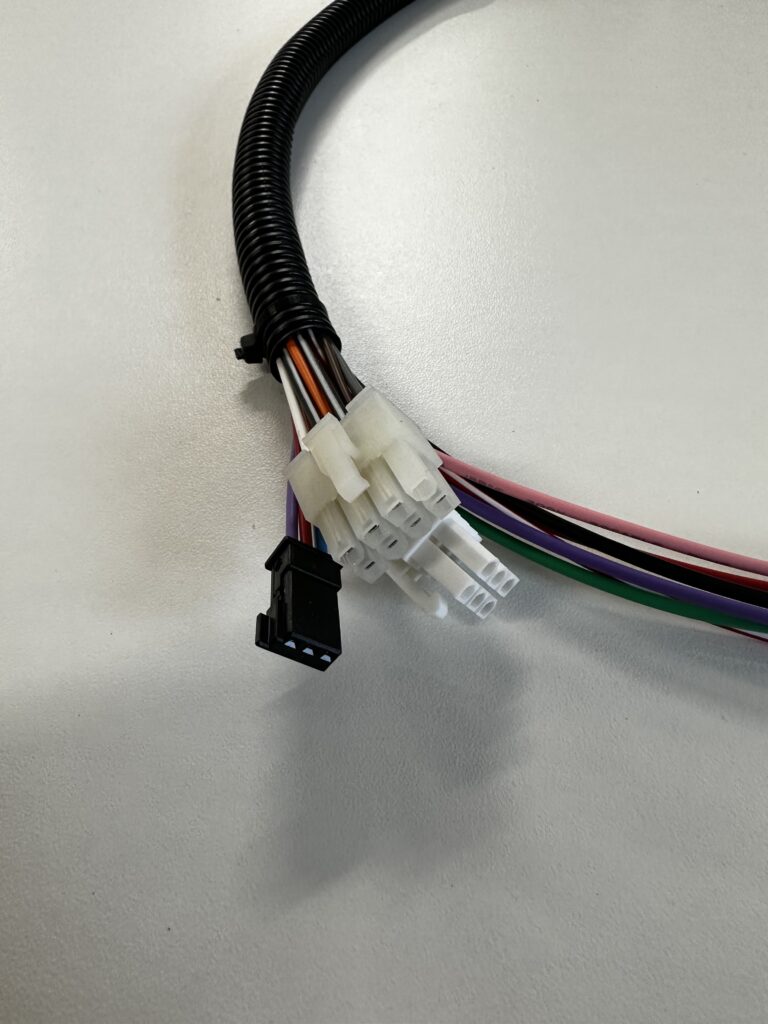

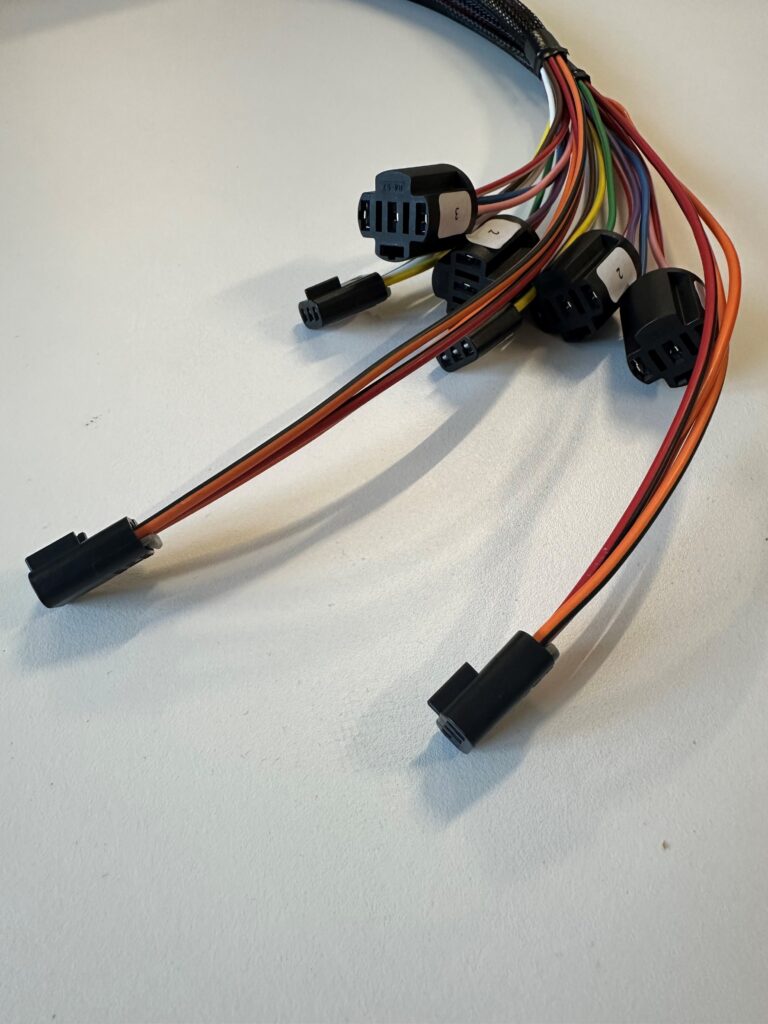

Automotive wire harnesses, often referred to simply as “wiring harnesses” or “cable assemblies,” are intricate networks of wires, cables, connectors, and protective components organised into a unified system.

These harnesses are designed to:

Connect Electrical Components: Wire harnesses link various electrical components, such as sensors, switches, lights, and control units, enabling them to communicate and function together harmoniously.

Ensure Safety: Properly designed and manufactured wire harnesses are critical for safety. They prevent short circuits, reduce the risk of electrical fires, and protect wires from environmental factors, like moisture and heat.

Simplify Installation: Automotive wire harnesses simplify the vehicle assembly process by providing pre-terminated connectors, which reduce labour costs and minimise the risk of installation errors.

Key Components of Automotive Wire Harnesses

Wires and Cables: The core of any wire harness, these conductors transmit electrical signals and power between components. They are carefully selected for their electrical properties and durability.

Connectors: Connectors are the interface points of the harness, allowing for easy attachment and detachment of components. They come in various shapes and sizes, depending on the specific application.

Protective Sheathing: Wire harnesses are often wrapped in protective sheathing, such as tape, braiding, or heat shrink tubing, to safeguard against abrasion, heat, moisture, and other environmental factors.

Circuit Protection: Inclusion of circuit protection components like fuses and relays prevents electrical overloads and short circuits.

Labelling and Identification: Harnesses are often labelled and colour-coded to facilitate easy installation and troubleshooting.

Customisation and Precision

Automotive wire harnesses from Pinnacle Harnesses are not one-size-fits-all. Manufacturers customise harnesses to meet the specific requirements of each vehicle model and its various subsystems. This level of customisation ensures precision and reliability, as well as compatibility with the vehicle’s electrical system.

The Role of Wire Harness Manufacturers

Wire harness manufacturing is a specialised field, and automotive manufacturers often partner with experienced harness suppliers who can design, produce, and deliver high-quality harnesses on time and within budget. These manufacturers adhere to strict quality standards and leverage advanced technology to create harnesses that meet or exceed industry specifications.

Whether it’s for a passenger car, a commercial vehicle, or an electric vehicle (EV), automotive wire harnesses are integral to the performance, safety, and longevity of modern automobiles.

Contact Us Today

At Pinnacle Harnesses, we take pride in our expertise in designing and manufacturing custom automotive wire harnesses. With a commitment to quality, innovation, and reliability, we are your trusted partner in harnessing the power of connectivity for the automotive industry.

For inquiries, quotes, or to learn more about our automotive wire harness solutions, please contact us today at 01978 437505 or use our online contact form and we’ll get back to you promptly.